Housetex, as a top home furniture manufacturer and supplier in China, offers a set of running colors and fabrics for our clients. Please see below:

PVC Color Swatches

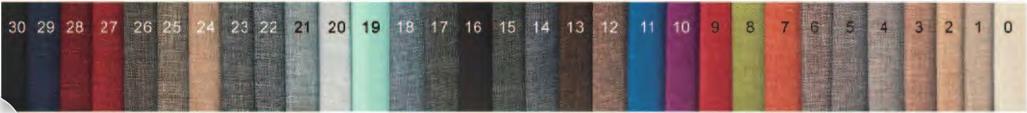

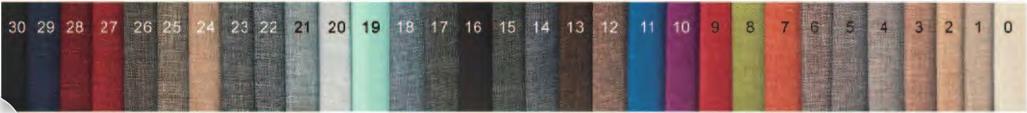

Polyester Linen Swatches

Velvet Color Swatches

These color swatches, serving as a great tool, are clear and straightforward where you can see colors next to each other having similar hues and blend seamlessly, as well as colors having the highest contrast. Various combination could create various atmosphere and effect.

For minimal order quantity (MOQ), Housetex normally accepts 500 pcs per color. If the client selects our running fabric and running color, 100 pcs or even 50pcs is also available. For fast order, if the client choose our running colors and fabric, Housetex can accelerate the delivery time to 25 days.

Of course we are extremely flexible if the client wants to specify a particular color beyond our swatches. What the client needs to do is to provide us a sample or Pantone color card.

Which Upholstery?

Come to upholstery materials, there are various fabrics to choose from. The right textures bring unique pattern, creative color or adorable sophistication. Our most popular materials include but not limited to the following:

- Cotton & Poly Blends – cotton, blended with polyester or other fabrics, will give you many different appearances, to name a few, linen, tweed or velvet. These blends are durable, and easy to work with, and we can add pleats, buttons or side ornamentation at the client’s needs.

- Leather / Artificial Leather – Leather or artificial leather has a stately look, usually reinforced with nail heads, suitable for traditional, contemporary or transitional decors. Some also comes with creative stitching.

- Faux or Fake Fur – long strands of faux or fake fur are fun. Housetex offers a metal leg stool using fake fur product which is perfect for a girl’s bedroom or dressing room. It currently has white and grey colors, but more bright colors at your requests also can be arranged on a customized basis.

- Wool Yarn – Ottomans that have a crocheted or knitted exterior will bring warm coziness to a house. Under this category, Housetex offers a round stool ottoman with pine wood legs. Its gentle pink wool yarn gives a homely look.

Last but not the least, fabric covered ottomans offer the greatest versatility. If you are looking for something for a big family, we are sure you would prefer a durable material or fabric that won’t fray or tear, and is easy to clean and forgiving on stains. In this case, we also suggest microfiber, polyester or nylon blends, which are washable and ideal for everyday use.

As a reliable household product manufacturer and exporter, we are now offering our series of furniture products in a variety of materials and functions, with efficient response, competitive pricing, best quality control and fastest delivery time to our clients.

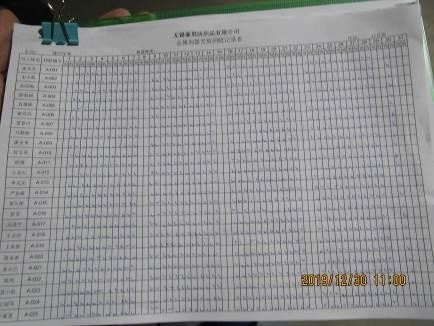

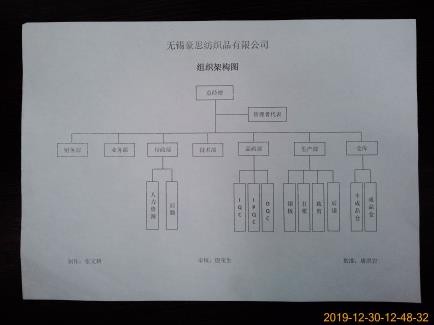

Advanced arts and crafts come from nowhere but our dedication and diligence. Housetex, one of the best Chinese furniture suppliers, has maintained a dedicated quality control department, currently consisting of twelve experienced inspection personnel. Each, selected from our manufacturing system and with abundant production expertise and knowledge, is capable to handle various demanding requests from our clients around the globe.

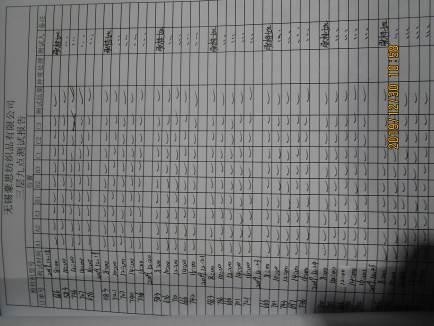

The details of our quality control system at Housetex are as below:

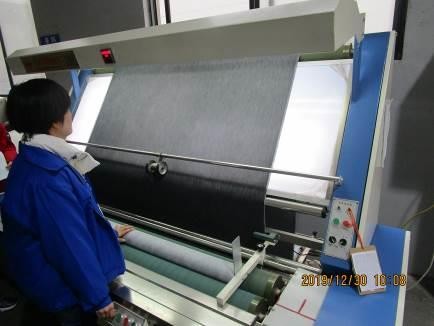

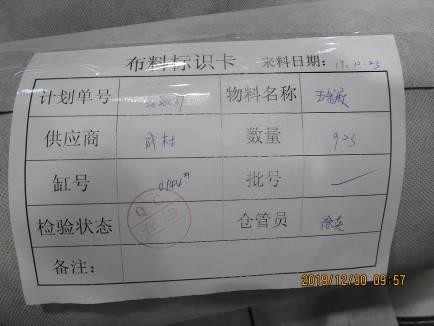

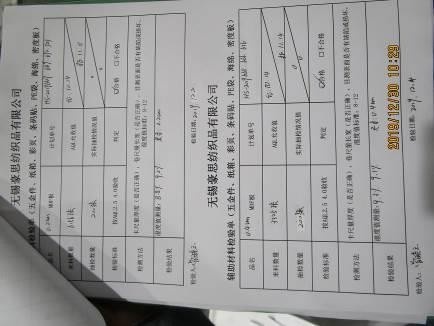

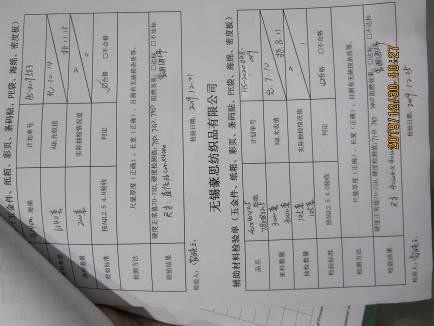

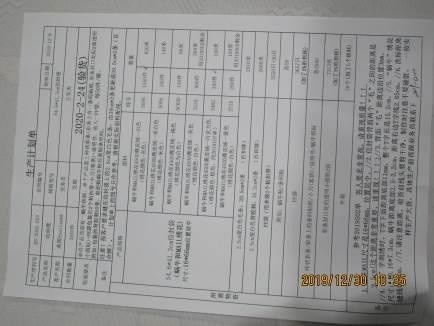

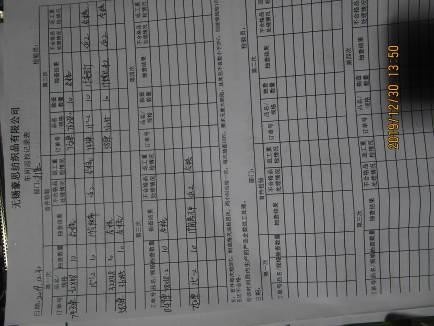

Raw materials and accessories

No raw materials or accessories shall enter our plant or our warehouse before our designated quality control personnel has visited the specific supplier concerned and has checked, either in the form of a random sampling inspection or full inspection, such raw materials or accessories. Only those satisfying our standards and requirements shall be allowed to enter our warehouse and be accepted as valid delivery.

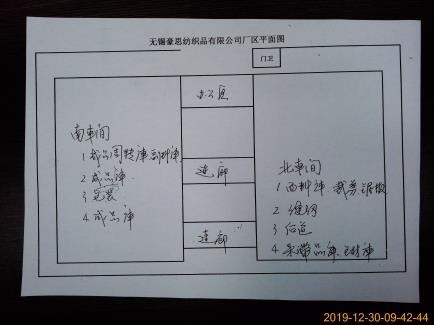

Production lines

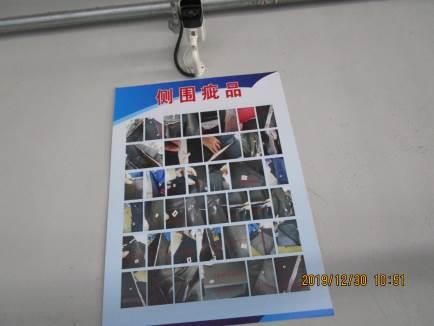

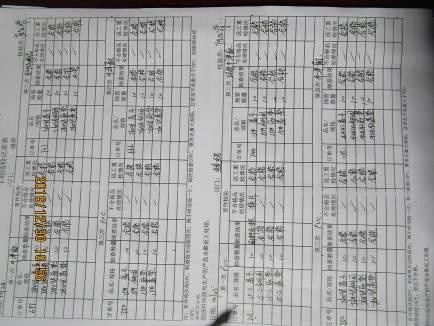

Our production lines are generally divided into two large sections, i.e., front-end and back-end of lines. For front-end production area which covers cutting process and sewing process, our quality control personnel shall carry out inspection of their cut pieces and quilted articles into every detail. For back-end production area which covers hemming process, board inserting process, cover making and nailing process, edge banding and bottom sealing process, all of their production activities are under the strict inspection by our quality control personnel on a constant basis.

Besides, we also include final upholstering process and packaging process in our back-end production area, and have equipped sufficient quality control personnel to carry out inspection over every finished product up to the very end of the packaging line.

In short, each and every process is under strict in-process quality audit and control, including but not limited to routing or random inspections.

Finished products

For every batch of finished products, our quality control personnel carry out sampling inspections on a random basis and only those satisfying our standards and requirements shall enter our warehouse in a strict and well-audited manner.

At the same time, we welcome any inspection tour from our client. A batch of products will not be ready for shipment until and unless the client concerned has completed its own inspection of the same at our site.

With our excellent dedication and service, we have voluntarily participated in a number of quality certification audits in accordance with internationally accepted quality control standards. For instance, Housetex has been awarded the Quality Management System Certificate since November 2009, which is a certificate issued by China Quality Certification Center to certify Housetex has a quality management system in compliance with the standard GB/T 19001-2016 /ISO 9001:2015 in the area of the manufacture of fabric art & artificial leather household products.

We have strived to render our best manufacturing service to our clients for over a decade and get recognized as a mark of quality excellence in many markets. Our major clients include but not limited to ALDI, LIDL, B&Q, Walmart, Costco, Carrefour, Bed Bath & Beyond, to name a few. We have determined to advance our business, improve our service and prepare ourselves to be a more accomplished and effective quality-focused professional ottoman manufacturer. We are confident to achieve and maintain our competitive advantage and global recognition, anywhere and anytime.

In addition, we always keep in mind that a win-win situation allows for increased understanding and mutual benefits for both parties. It cultivates stronger commitments and encourages a greater interest in success for the materials and finished products. With our relationship grows stronger, we believe our clients will become more integrated into our manufacturing process with their ideas and concepts. We have achieved a certified status with many big names including LIDL and Walmart with our sustained successful performance. We have been issued and maintained a certificate of registration, certifying our compliance with the requirements of FSC Standards for the scope including tracking of wood based materials.

As a top lifestyle furniture manufacturer and exporter in China, the ultimate goal of Housetex is to form a strategic, long term partnership with our clients around the globe, allowing full knowledge of the sources of materials and ensuring timely delivery of high-quality ottoman and other household products all the times.